As craftsmen in high-volume, multi-cavity and multi-mold projects, Precise Tooling is the preferred mold builder for manufacturers in the automotive, aerospace consumer goods, medical device and defense industries. Our custom injection molds are designed for manufacturability and machined to hold very tight tolerances that save manufacturers money. We provide turnkey service – from initial design through on-time delivery.

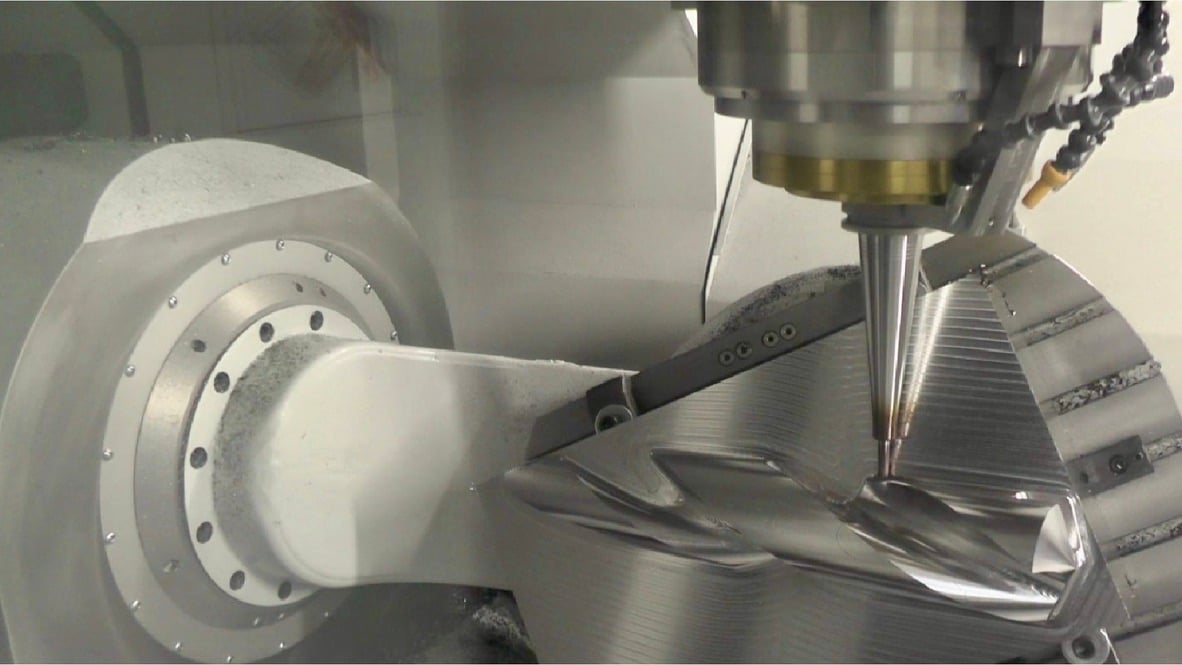

Whether it’s a routine steel plate or a steel fixture table top, we take immense pride in our CNC machining capabilities. Our craftsmen use the latest five-axis machining centers, EDMs and boring mills to meet your toughest expectations. Our deep experience in CNC machining virtually guarantees that we've solved a problem like yours before. Few can match the lead times, world-class quality, and prices we offer.

Leading manufacturers have used ErgoStation® manufacturing cells to drive manufacturing efficiency for over 20 years. These height-adjustable workstations and machine bases feature a full 12" range of motion to provide optimal ergonomic safety. And their unique design allows the workstations and machine bases to be configured for virtually any type of manufacturing setting.

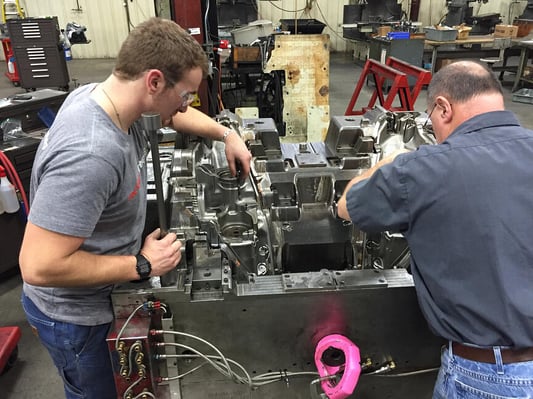

Delayed tool maintenance and postponed engineering changes put your production at risk. Stay ahead of this risk by partnering with the Midwest’s premiere tool repair & engineering shop. We dedicate a team of experienced craftsmen solely to your mold repair & engineering projects. Managing repair projects has been central to our business model model for 35+ years.

Customers trust us to build injection tools many other mold builders won't tackle. Our craftsmen have the experience and industry knowledge needed to build today's complex tools.

Every aspect of the project went very smooth. Your craftsmen are extremely easy to work with.

- Toyoda Gosei

Prices are vary competitive.- NAL

Communication was a key part of the project and I had a direct line whenever needed.- Valeo

Just a couple of words will sum up everything you guys do for us: excellent quality, communication and on-time delivery.- Aura Systems

Have exceeded our expectations on quality, and delivery has been on time.- Ahaus Tool & Engineering

Excellent craftsmanship and on-time delivery.- A&A Automation

Mold ran well. Plate work always good.- TASUS

I had many questions prior to authorizing this project. Each issue was explained and priced in advance.- Eastern Automation

Delivery time was excellent - improved from quoted date!- Photon Automation

Precise Tooling Solutions, Inc. is a specialty manufacturer that builds and repairs injection tooling. We are recognized for our expertise with tight-tolerance optical lighting tools & thermoset molds. We also manage complex CNC machining projects and build ErgoSmart, a line of adjustable-height workstations and lift tables which manufacturers use for assembly and material handling applications. We also have a thorough top of the line equipment list.

© 2019 PRECISE TOOLING SOLUTIONS, INC. ALL RIGHTS RESERVED SITEMAP

PRIVACY POLICY | WEBSITE DISCLAIMER & COPYRIGHT NOTICE | EQUIPMENT LIST