We built our reputation over 30+ years by providing on-time delivery of high-quality projects to the most demanding customers. Customers benefit from our massive arsenal of CNC equipment, including EDMs, large capacity horizontal and vertical mills, and grinding machinery. And our commitment to the 5-axis technology and the latest design software has dramatically reduced setup and machining times, while improving the quality and consistency of CNC projects.

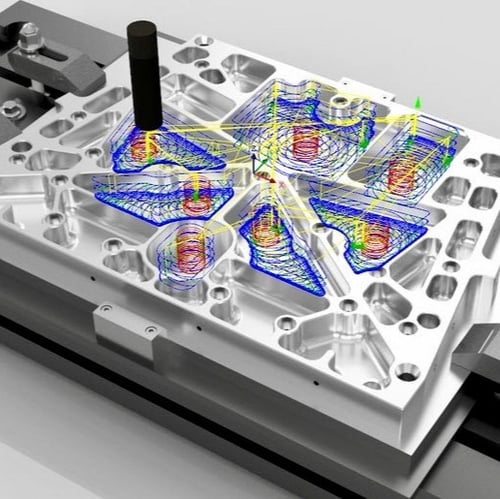

Manufacturing is experiencing unprecedented levels of change. 5-axis machining is a prime example. However, exploiting the full capabilities of 5-axis hardware cannot be achieved without equally capable software.

We use Autodesk PowerMill, PowerShape & Fusion 360 to achieve or exceed the tolerance requirements on your projects. Whether calculating dynamic toolpaths for complex parts or designing electrodes for EDM, this incredibly powerful software provides our craftsmen with a wholistic view within one seamless software environment. That translates into shorter lead times with the highest possible precision.

Roeders and Fermat build some of the world’s most precise machining centers. Our ongoing investment in 5-axis technology has dramatically reduced setup and machining times, while improving the quality and consistency of the tooling we build.

These incredible machines use shorter cutting tools that enable higher cutting speed and reduced tool vibration. Advanced spindles with up to 67Nm torque and 30,000 rpm allow a large variety of applications. This game-changing technology means you'll benefit from unprecedented precision and shorter lead times.

Electrical discharge machining (EDM) is a metal removal process in which thousands of electrical discharges per second occur between an electrode and the workpiece in a dielectric fluid. It has the effect of vaporizing metal in a very small controlled area.

Our craftsmen use both sinker and wire EDMs to cut complex shapes and tapered holes with extremely tight tolerances. Programmable CNC controls and electrode machining enable stable, accurate, and lights-out machining, which allows us to accommodate quick-turn projects with aggressive deadlines.

With our strong engineering, design, and manufacturing capabilities, we're known for managing projects that require an elevated level of technical sophistication. Our team has hundreds of years experience in advanced precision machining, and they’re recognized across the midwest for managing complex projects from concept through delivery.

Need blanchard grinding? Our large Blanchard grinders can easily handle oversize grinding projects as large as 120 x 95 inches. And the huge 156” x 78” travel on our 5-axis Fermat boring mill makes fast work on oversize & complex projects.

Shoptech's ERP software is fully integrated across our manufacturing facility. It handles the RFQ process, manages orders, and tracks the entire fabrication process in a secure digital environment.

Our platform handles the documentation and communication making ordering, receiving, and purchasing simple.

Plate Rings

Machine Gear

V-Band Clamps

Plate Rings

Slide Parts

Jig Plate

Ground Rings

Machined Die Set

Universal Joint

Ejector Plate

Precise Tooling Solutions, Inc. is a specialty manufacturer that builds and repairs injection tooling. We are recognized for our expertise with tight-tolerance optical lighting tools & thermoset molds. We also manage complex CNC machining projects and build ErgoSmart, a line of adjustable-height workstations and lift tables which manufacturers use for assembly and material handling applications. We also have a thorough top of the line equipment list.

© 2019 PRECISE TOOLING SOLUTIONS, INC. ALL RIGHTS RESERVED SITEMAP

PRIVACY POLICY | WEBSITE DISCLAIMER & COPYRIGHT NOTICE | EQUIPMENT LIST