Today's Tooling Requires Tight Tolerances

Today's Tooling Requires Tight Tolerances

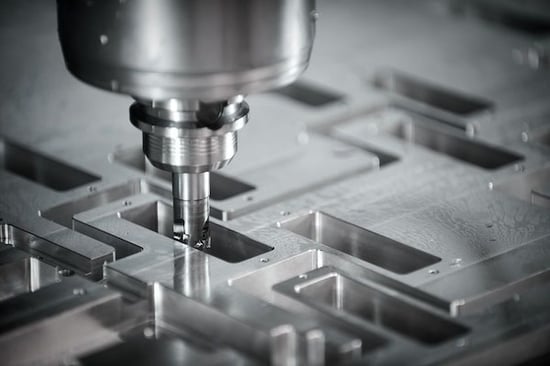

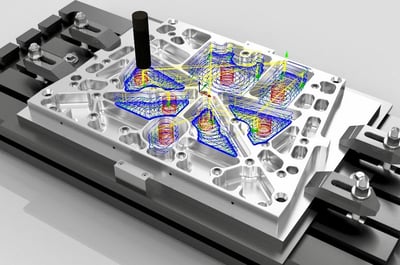

Our Roeders 5-Axis milling machine provides accuracy within 5 microns. That’s an optic-quality finish directly from the machine! This level of precision virtually eliminates the need for EDM and manual polishing. We’ve paired PowerMill's new CAM software with our Roeders high speed machine, too. This technology combination enables our craftsmen to deliver the complex design features you need at your targeted price.

Our craftsmen build dozens and repair hundreds of molds every year for leading manufacturers in the automotive, consumer goods, aerospace, medical device and defense industries. And with 30+ years of experience, we aren't afraid to tackle the complex projects our competitors avoid.

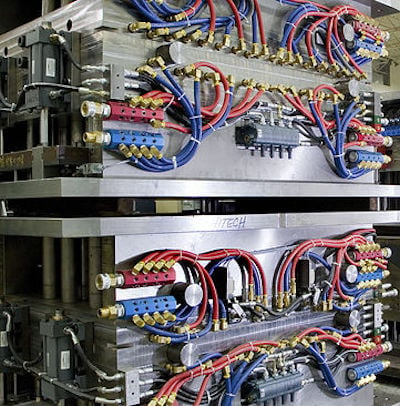

Our craftsmen use high-speed mills to achieve the dimensional accuracy that is key to Thermoset molding. In fact, we deliver flash-free Thermoset tools that go straight into production. And with 20+ years of thermoset experience, our team understands when to use specialty steel, optimal placement of heaters and sensors, and appropriate coatings.

Click below to watch short videos the multi-axis technology we use. You'll see one of our craftsman programming the Roders 5-axis for a Thermoset/BMC tool for automotive headlight brackets.

The major benefit of five-axis machining is the ability to mill highly complex shapes in a single set-up. Our ongoing investment in 5-axis technology has dramatically reduced setup and machining times, while improving the quality and consistency of the tooling we build.

These incredible machines use shorter cutting tools that enable higher cutting speed and reduced tool vibration. Advanced spindles with up to 67Nm torque and 30,000 rpm allow a large variety of applications. This game-changing technology means you'll benefit from unprecedented precision and shorter lead times.

Manufacturing is experiencing unprecedented levels of change. 5-axis machining is a prime example. However, exploiting the full capabilities of 5-axis hardware cannot be achieved without equally capable software.

We use Autodesk PowerMill, PowerShape & Fusion 360 to achieve tight-tolerance and highly-accurate requirements on your projects. Whether calculating dynamic toolpaths for complex parts or designing electrodes for EDM, this incredibly powerful software enables our craftsmen to connect the dots between design and manufacturing within one seamless software environment. Your tools and parts are machined faster, and with the highest-possible precision.

Electrical discharge machining (EDM) is a metal removal process in which thousands of electrical discharges per second occur between an electrode and the workpiece in a dielectric fluid. It has the eff ect of vaporizing metal in a very small controlled area.

Our craftsmen use both sinker and wire EDMs to cut complex shapes and tapered holes with extremely tight tolerances. Programmable CNC controls and electrode machining enable stable, accurate, and unattended machining at breakneck speeds, which allows us to accommodate quick-turn projects with aggressive deadlines.

Production schedules can accommodate preventive maintenance; that's why we proactively talk with our customers about their scheduled shutdowns. Our team will work around your schedule to evaluate mold surfaces, make engineering changes or conduct preventive maintenance.

We have deep experience with productivity enhancements on molds we didn’t build--including foreign. Our advanced sampling press ensures your tool is 100% functional. And our drivers use trucks we own to pick up and deliver your tools. Less time on the dock means less down time.

Spoon Mold

Slide Ejectors

Child Seat

Repair Project

Headlight Mold

Mold & Housing

Tight Tolerance Part

Reflector Lens

Lawn Wheel

Air Filtration

Headlamp Housing

Floral Vase

Safety Seat

Safety Seat

Headlight Assembly

Lighting Lens

Fan Shroud

LED Pipe

Precise Tooling Solutions, Inc. is a specialty manufacturer that builds and repairs injection tooling. We are recognized for our expertise with tight-tolerance optical lighting tools & thermoset molds. We also manage complex CNC machining projects and build ErgoSmart, a line of adjustable-height workstations and lift tables which manufacturers use for assembly and material handling applications. We also have a thorough top of the line equipment list.

© 2019 PRECISE TOOLING SOLUTIONS, INC. ALL RIGHTS RESERVED SITEMAP

PRIVACY POLICY | WEBSITE DISCLAIMER & COPYRIGHT NOTICE | EQUIPMENT LIST